In the realm of supply chain management, the terms “supply” and “inventory” are crucial yet often misunderstood. Supply refers to the total resources available to meet demand, while inventory pertains specifically to goods held by a business for sale or production. This distinction is vital for effective management strategies. VVAP Global, a leading provider of Third-Party Logistics (3PL) and supply chain solutions, plays an essential role in optimizing both supply and inventory for businesses seeking to enhance their operational efficiency.

What is Supply?

Definition of Supply

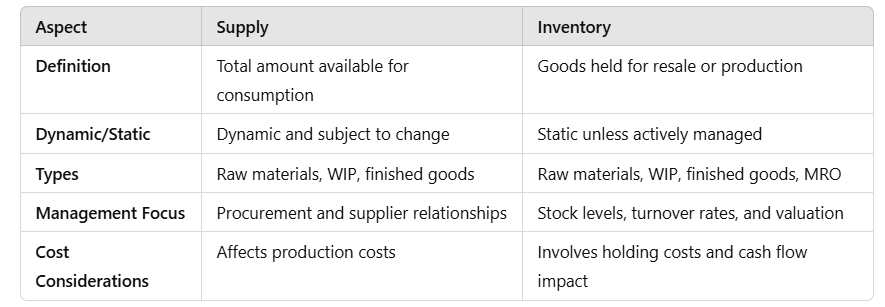

Supply encompasses the total amount of products and services available for consumption or purchase at any given time. It includes raw materials, work-in-progress (WIP), and finished goods, all critical for businesses to meet customer demands effectively.

Types of Supply

- Raw Materials: The basic inputs used in the manufacturing process, such as metals, plastics, or agricultural products.

- Work-In-Progress (WIP): Items currently in production, reflecting the ongoing effort to create finished goods.

- Finished Goods: Products that are completed and ready for sale, representing the end of the production cycle.

Characteristics of Supply

- Dynamic Nature: Supply levels fluctuate based on market demand, production capabilities, and external factors like seasonal trends or economic shifts.

- Time Sensitivity: Proper timing in supply acquisition is crucial to prevent shortages or excess inventory, impacting overall business operations.

- Cost Considerations: Effective supply management minimizes costs while maximizing availability, ensuring that businesses can compete in a dynamic market.

Importance of Supply Management

Effective supply management is key to maintaining business efficiency. It helps in:

- Cost Reduction: Minimizing waste and optimizing procurement strategies to lower overall expenses.

- Customer Satisfaction: Ensuring product availability aligns with customer needs, fostering loyalty and repeat business.

- Competitive Advantage: Businesses excelling in supply management can swiftly adapt to market changes, positioning themselves favorably against competitors.

What is Inventory?

Definition of Inventory

Inventory refers to the stock of goods and materials a business holds for production or sale. It is a critical asset, impacting cash flow and operational efficiency.

Types of Inventory

- Raw Materials: Unprocessed materials needed for production, forming the foundation of the manufacturing process.

- Work-In-Progress (WIP): Items being produced but not yet complete, representing the ongoing efforts within the production line.

- Finished Goods: Completed products ready for distribution to customers or retail outlets.

- Maintenance, Repair, and Operations (MRO): Supplies necessary for ongoing business operations, such as cleaning supplies or repair parts.

Characteristics of Inventory

- Static Nature: Unlike supply, inventory can remain constant unless actively managed; businesses need to monitor stock levels to avoid discrepancies.

- Valuation: Inventory contributes significantly to a company’s financial health, representing a major portion of assets on the balance sheet.

- Holding Costs: These are expenses associated with storing unsold goods, including warehousing, insurance, and depreciation, which can erode profit margins.

Importance of Inventory Management

Effective inventory management is crucial for businesses to maintain optimal stock levels and minimize costs. It enables:

- Cash Flow Optimization: Reducing excess stock frees up capital for other business needs, improving overall liquidity.

- Enhanced Customer Experience: Ready availability of products fosters customer loyalty and satisfaction, leading to repeat purchases.

- Operational Efficiency: Streamlined inventory processes mitigate stockouts and overstock scenarios, ensuring smooth business operations.

Key Differences Between Supply and Inventory

The Interrelationship Between Supply and Inventory

While supply and inventory are distinct, they are intricately linked. Effective management of supply directly influences inventory levels. For example, if VVAP Global can provide timely supply of materials, businesses can maintain optimal inventory levels, reducing costs and enhancing service delivery. Conversely, poor inventory management can lead to increased supply costs due to rushed orders or excess holding.

The Role of Supply Chain Management

Supply chain management is the backbone of effectively coordinating supply and inventory. It includes:

- Demand Forecasting: Anticipating customer needs to ensure adequate supply and inventory levels, allowing businesses to react quickly to market changes.

- Supplier Management: Building strong relationships with suppliers for reliable access to materials and products, reducing lead times and improving quality.

- Inventory Control: Implementing strategies to optimize inventory levels and minimize holding costs, ensuring businesses have the right products at the right time.

VVAP Global’s Role in Supply and Inventory Management

Comprehensive Supply Chain Solutions

VVAP Global offers integrated supply chain solutions that streamline both supply and inventory management. Our services ensure businesses can operate efficiently and effectively through:

Demand Forecasting and Planning: Our advanced analytics tools provide insights into market trends, helping businesses predict demand accurately. This proactive approach minimizes the risk of overstock or stockouts, allowing companies to align their supply chain with actual customer demand.

Supplier Relationships: VVAP Global works with a network of reliable suppliers, ensuring businesses have consistent access to quality materials at competitive prices. Our established relationships allow us to negotiate better terms and maintain a steady flow of supplies.

Inventory Optimization: We employ state-of-the-art inventory management systems that minimize holding costs and prevent stockouts. By analyzing sales patterns and turnover rates, we help businesses maintain optimal inventory levels, thereby improving cash flow and reducing waste.

Logistics Management: Our logistics solutions facilitate efficient movement of goods, ensuring timely delivery and reducing lead times. By handling logistics, VVAP Global allows businesses to focus on core operations while we manage the complexities of the supply chain.

Technology Integration: We utilize advanced technology platforms that offer real-time visibility into supply and inventory levels. This integration enables businesses to make informed decisions quickly, enhancing responsiveness to market changes.

Tailored Solutions for Different Industries

VVAP Global understands that different industries have unique supply and inventory needs. We provide tailored solutions for various sectors, including:

E-Commerce: For online retailers, we optimize order fulfillment processes, ensuring fast shipping and customer satisfaction. Our technology integrates with popular e-commerce platforms, providing seamless order processing and real-time inventory tracking.

Manufacturing: We streamline material handling and supply chain operations, helping manufacturers reduce downtime and improve production efficiency. Our solutions include just-in-time inventory systems that ensure materials arrive precisely when needed, minimizing excess inventory and associated costs.

Retail: Our solutions assist retailers in managing inventory turnover and optimizing shelf space to meet consumer demand effectively. By implementing analytics-driven restocking strategies, we help retailers maintain popular items in stock while reducing excess.

Case Study: E-Commerce Optimization

Consider an e-commerce client that experienced fluctuating demand patterns, leading to stockouts during peak seasons. VVAP Global implemented a demand forecasting tool that analyzed historical sales data, seasonal trends, and marketing campaigns. By accurately predicting demand, the client was able to adjust their inventory levels proactively, resulting in a 30% reduction in stockouts and a 15% increase in customer satisfaction.

Commitment to Sustainability

At VVAP Global, we prioritize sustainability in our operations. We work with partners who share our commitment to environmentally friendly practices, ensuring that our supply chain solutions contribute to a sustainable future. This includes optimizing transportation routes to reduce carbon emissions and sourcing materials from sustainable suppliers.

Best Practices for Managing Supply and Inventory

1. Utilize Technology

Implementing supply chain management software provides real-time insights into supply and inventory levels, enabling better decision-making. VVAP Global leverages cutting-edge technology to ensure that clients have access to the best tools available, enhancing their operational capabilities.

2. Conduct Regular Audits

Regular audits of both supply and inventory can help identify inefficiencies and areas for improvement. VVAP Global assists clients in conducting these audits to maintain optimal performance and adapt to changing market conditions.

3. Foster Supplier Relationships

Building strong relationships with suppliers leads to better communication, reliability, and terms. VVAP Global emphasizes the importance of these relationships in our supply chain management approach, ensuring consistent quality and timely deliveries.

4. Implement Just-In-Time (JIT) Inventory

The JIT approach minimizes inventory levels by synchronizing supply with production schedules, reducing holding costs. VVAP Global can help businesses adopt JIT strategies tailored to their needs, ensuring efficiency without compromising on availability.

5. Analyze Data

Using data analytics to track supply chain performance helps businesses identify trends and make informed decisions. VVAP Global provides analytical tools that empower clients to optimize their operations continually, staying ahead of market fluctuations.

6. Employee Training

Investing in training for employees on supply and inventory management practices can significantly improve overall performance. VVAP Global offers training programs that equip teams with the skills needed to effectively manage their supply chain.

Conclusion

Understanding the difference between supply and inventory is essential for businesses aiming to optimize their operations and enhance customer satisfaction. By recognizing the unique characteristics of each and implementing effective management practices, organizations can achieve greaterinformation.

VVAP Global offers tailored solutions that integrate supply and inventory management to drive efficiency and profitability for businesses across various sectors. By understanding the distinctions and interrelationships between supply and inventory, and leveraging our expertise, companies can enhance their operations and meet customer demands effectively.